Why might India have missed its last chance to revive its manufacturing sector?

为什么印度可能已经错失了发展制造业的最后机会?

以下是Quora读者的评论:

Raquel Veile

India has been grappling to revive manufacturing sector under the weight of decades of policy inertia, poor infrastructure and complex labour laws that make investment unappealing. India found itself overshadowed by global competition from China and southeast Asia, which offered cheaper labor and which had efficient supply chains.

The pandemic-led supply chain diversion offered opportunities, but slow progress on land acquisition, taxation and red tape stymied industrialisation. A growing tech sector shifted attention to services and away from manufacturing requirements. Lack of skills at scale, not to mention low productivity, further hindered scaling.

At the same time, more automation and global protectionism diminished the appeal of labor-intensive models. In the absence of timely upgrades in infrastructure, a policy framework that streamlines execution and the development of an appropriate workforce, India will lose its relevance in manufacturing as markets shift to advanced technology and regional players consolidate dominance.

印度一直以来都在艰难地发展制造业,这是因为几十年来政策上的惯性、糟糕的基础设施,以及复杂的劳动法使得投资缺乏吸引力。印度发现自己在全球竞争中被中国和东南亚地区所掩盖,这些地区提供了更廉价的劳动力,并且拥有高效的供应链。

疫情引发的供应链转移带来了机遇,但在土地征收、税收以及繁文缛节方面进展缓慢,阻碍了工业化进程。不断发展的科技行业将注意力从制造业的需求上转移开,转向了服务业。大规模技能的缺乏,更不用说生产率低下,进一步阻碍了制造业规模的扩大。

与此同时,更多的自动化以及全球保护主义降低了劳动密集型模式的吸引力。如果没有及时对基础设施进行升级,没有一个能简化执行的政策框架,也没有培养出合适的劳动力队伍,随着市场向先进技术转移,以及地区参与者巩固其主导地位,印度将在制造业领域失去重要性。

Mihir Chaudhari

today’s article on failure in luring China plus one supply chain manufacturers to setup in India.

今天有媒体发表了印度在吸引中国及其他供应链制造商在印设厂方面失败的文章。

Kanthaswamy Balasubramaniam

R C E P

Four words that could haunt India for a long time to come

A 160 AH battery made with Chinese cells and Indian assembly costs ₹15,000/- including GST

Without Tariffs on those Chinese cells, the same 160 AH battery would cost ₹ 9,633/- including GST

The Indian company would still have made the same profit!!!

You and I would have saved up ₹ 5,367/- which we could have used as Disposable income

Your Electric Scooter with 150 Km Range costing ₹ 1,50,000/- would be costing you ₹ 1,07,000/- for the same profit margin

《区域全面经济伙伴关系协定(RCEP)》

这四个字可能会在未来很长一段时间内困扰着印度

一个使用中国电芯、在印度组装的160安时的电池,含商品及服务税(GST)售价为15000卢比

如果对那些中国电芯不征收关税,同样的160安时的电池,含商品及服务税售价仅为9633卢比

印度公司仍然可以获得相同的利润!!!

你和我原本可以省下5367卢比,这笔钱可以用作可支配收入

一辆续航里程为150公里、售价15万卢比的电动滑板车,在相同利润率的情况下,本可以只卖10.7万卢比

You would have saved ₹43,000/- which would have been spent as disposable income or saved up

Your Iphone of ₹1,70,000/- would have cost ₹ 1,39,000/- saving you ₹ 31,000/- with the same profit margins

Lower the cost of imported supplies= Lower the cost of production = Competitive Export price

Simple equation

Higher the cost of imported supplies = Higher the cost of production = Uncompetitive Export Price

Vietnam buys the same supplies and equipment from China as India but because of RCEP , the Importers pay almost 24% less than India

($ 10,000 in India vs $ 7,610 in Vietnam)

你原本可以省下43000卢比,这笔钱可以作为可支配收入花掉,或者存起来

一部售价17万卢比的苹果手机,在相同利润率的情况下,本可以只卖13.9万卢比,这样你就能省下31000卢比

进口物资成本降低 = 生产成本降低 = 出口价格更具竞争力

就是这么简单的等式

进口物资成本升高 = 生产成本升高 = 出口价格缺乏竞争力

越南和印度从中国购买相同的物资和设备,但由于《区域全面经济伙伴关系协定》(RCEP),越南的进口商支付的费用比印度低近24%

(在印度是10000美元,而在越南是7610美元)

As a result, Vietnam sells Textiles at 15% to 25% lower prices than India

India has lost almost 30% market share in the past 3 years to Vietnam, Bangladesh and get this..PAKISTAN

Electronics?

Same story

An Air Conditioner costs ₹33,000/- in India but would cost ₹ 22,000/- under the RCEP with the same profit margin for the factory

More people could afford it and saved money

So India makes electronics that are at least 35% more expensive than Vietnam, Thailand and some others

India initially exted the RCEP due to Medical parents but soon they were agreed upon

Yet due to Galwan India stupidly refused and handed over manufacturing to Vietnam, Thailand, Cambodia and Indonesia on a platter

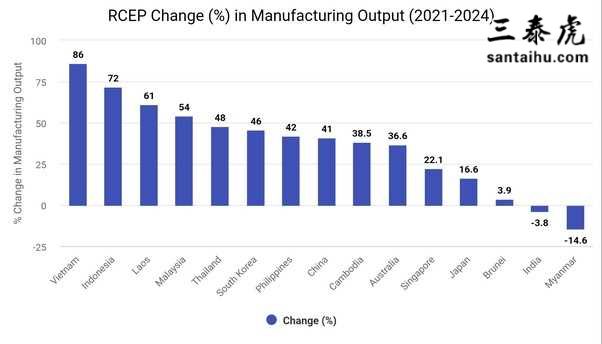

Indias manufacturing output fell (-)4% from the time of the RCEP, worse than every other country except Myanmar who had a near internal strife within it's boundaries

It should have been at least 20% , had India signed the RCEP

结果,越南纺织品的售价要比印度低15%到25%

在过去三年里,印度已经把近30%的市场份额输给了越南、孟加拉国,甚至还有……巴基斯坦

电子产品方面呢?

情况也是一样

一台空调在印度售价33000卢比,但在《区域全面经济伙伴关系协定》框架下,在工厂利润率相同的情况下,售价仅为22000卢比

这样更多人就能买得起空调,还能省下钱

所以,印度生产的电子产品至少要比越南、泰国以及其他一些国家生产的贵35%

印度最初因为医药相关问题退出了《区域全面经济伙伴关系协定》,但很快这些问题就达成了共识

然而,由于加勒万河谷事件,印度愚蠢地拒绝加入,拱手把制造业的机会让给了越南、泰国、柬埔寨和印度尼西亚

自《区域全面经济伙伴关系协定》相关事宜推进以来,印度的制造业产出下降了4%,除了陷入内部纷争的缅甸之外,印度的情况比其他任何国家都要糟糕

如果印度当初签署了《区域全面经济伙伴关系协定》,其制造业产出至少应该增长20%

India has bad leaders

Fine , we can live it with

India has stupid leaders

Fine, we can still manage

India has corrupt leaders

Fine, we can someone plod along

India has stupid brainwashed citizens

Okay, we can somehow crawl and crawl and crawl

India has bad, stupid and corrupt leaders and stupid brainwashed citizens!!!!

We are royally s*****d

Now that Make in India is an official disaster

What is next?

AI?

印度的领导人太糟糕了

好吧,我们可以忍受

印度有愚蠢的领导人

好吧,我们仍然可以应付

印度有腐败的领导人

好吧,我们还能勉强维持

印度有被洗脑的愚蠢民众

好吧,我们还能勉强度日

但印度有糟糕、愚蠢且腐败的领导人,还有被洗脑的愚蠢民众!

我们可真是倒了八辈子霉了

既然“印度制造”已经彻头彻尾地失败了

接下来该怎么办呢?

人工智能?

Quantum space?

Teleportation?

Space Shuttle?

Now India can revive it's manufacturing sector

Unfortunately the whole world has decided to do the same thing

Including our orange friend in DC

So no more manufacturing FDI and no more RCEP

Local investment?

Nopes

We pay 27% of our revenue in Interest. We have too much debt to raise anymore

So what is the only chance India has ?

Go back to China like Goundamani

Maybe Modi realized which way the wind is blowing and is changing tact?

No matter what, China wont trust India again and I don't see any way in which Indian manufacturing scenario changes

We don't have the money and we just chased out largest investor away

量子空间领域?

瞬间移动技术?

航天飞机?

现在印度本可以重振其制造业

不幸的是,全世界都决定这么做

包括我们那位在华盛顿特区的“橙色”朋友(指美国)

所以不会再有制造业方面的外国直接投资(FDI),也不会再加入《区域全面经济伙伴关系协定》了

那国内投资呢?

不行

我们收入的27%都用来支付利息了。我们负债累累,无法再筹集更多资金了

那么印度仅有的机会是什么呢?

像(印度喜剧演员)古达马尼那样再回到中国(寻求合作)?

也许莫迪意识到了形势的变化,正在改变策略?

不管怎样,中国不会再信任印度了,而且我看不到印度制造业的情况有任何改变的可能

我们没有钱,而且我们刚刚把最大的投资者赶走了

Ute Kraus

India’s struggle to revive manufacturing stems from persistent structural challenges. Inadequate infrastructure - poor logistics, erratic power supply, and inefficient ports - raises costs and deters investment. Complex labor laws hinder flexbility, discouraging large-scale industrial hiring. Bureaucratic delays and land acquisition hurdles slow project implementation, while competing nations like Vietnam and Bangladesh offer more attractive policies and lower costs.

Global shifts toward automation and reshoring reduce reliance on cheap labor, eroding India’s potential advantage. Meanwhile, the economy’s focus on services and IT diverted attention from manufacturing, delaying critical reforms. Post-pandemic supply chain realignments prioritized agility over cost, favoring established hubs. Without swift, cohesive reforms in infrastructure, regulation, and labor, India risks losing its window as global dynamics evolve beyond labor-intensive models.

印度重振制造业,之所以困难重重,源于长期存在的结构性挑战。基础设施不完善——物流条件差、电力供应不稳定以及港口效率低下——这些问题增加了成本,让投资者望而却步。复杂的劳动法限制了灵活性,使得大规模的工业雇工难以实现。官僚程序导致的延误以及征地方面的障碍,使得项目推进缓慢,而越南和孟加拉国等与之竞争的国家却能提供更具吸引力的政策和更低的成本。

全球范围内向自动化和产业回流的转变,降低了对廉价劳动力的依赖,这也削弱了印度潜在的优势。与此同时,印度经济对服务业和信息技术领域的关注,使得人们的注意力从制造业上转移开,从而推迟了关键改革的实施。疫情之后,供应链的重新调整更加注重灵活性而非成本,这使得那些已有的产业中心更具优势。

如果不在基础设施、监管和劳动力等方面迅速且协调一致地进行改革,随着全球发展趋势逐渐超越劳动密集型模式,印度可能会错失发展的机遇之窗。

此文由 三泰虎 编辑,未经允许不得转载!:首页 > 资讯 » 印度可能已经错失了发展制造业的最后机会

在“印度制造”政策的号召下,印度大力推销本国制造的武器

在“印度制造”政策的号召下,印度大力推销本国制造的武器 “印度制造” 与 “美国优先” 能够共存吗

“印度制造” 与 “美国优先” 能够共存吗 印度制造失败了吗

印度制造失败了吗 印度制造,是制造还是组装

印度制造,是制造还是组装 世界银行:印度制造业输给了越南和孟加拉国等较小的竞争对手

世界银行:印度制造业输给了越南和孟加拉国等较小的竞争对手 印度真的能成为全球制造业强国吗

印度真的能成为全球制造业强国吗 比哈尔制造,俄罗斯军人穿着印度制造的靴子

比哈尔制造,俄罗斯军人穿着印度制造的靴子 法国送给印度的礼物,阵风战斗机将在印度制造,达索公司在诺伊达购买土地

法国送给印度的礼物,阵风战斗机将在印度制造,达索公司在诺伊达购买土地